We look forward to providing you with professional services - Zhongda Leader

-

-

-

RV Cycloidal Pin Wheel Reducer

PRODUCTS

+Detail

■ Product Information

The transmission system of space, low noise and high power transmission equipment has special requirements for the use of DM1 13A, high alloy steel gear and special high precision assembly method of grinding with fine the running noise and the power requirements, meet customer requirements: This product is widely used in the fllowing industries precision assembly method of grinding with fine the running noise and the power requirements, meet customer requirements: This product is widely used in the fllowing industries

· Security machine

· Airport baggage handling system

· Packing machinery

· Power belt scale

· Pharmaceutical industry

· Food processing industry

· Meat processing industry

· Postal sorting

· Belt conveyor

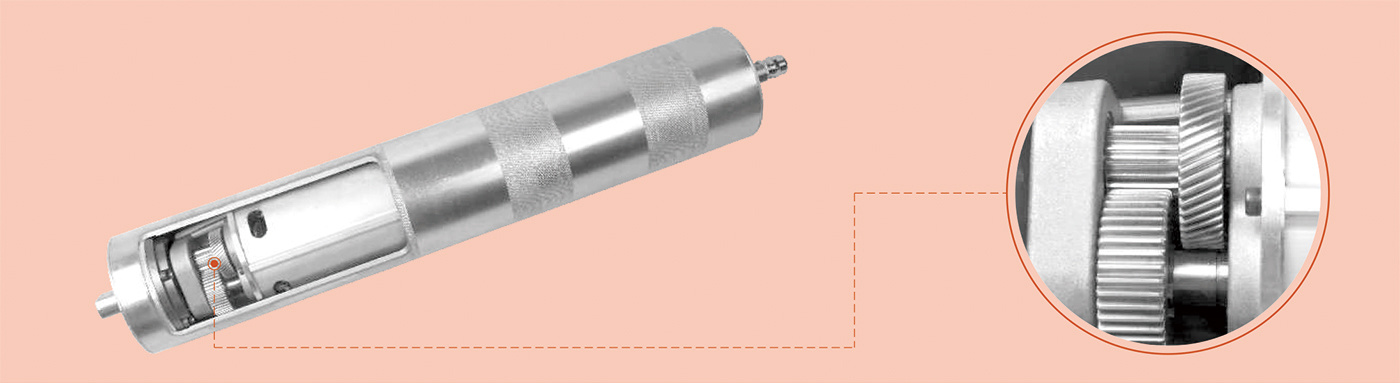

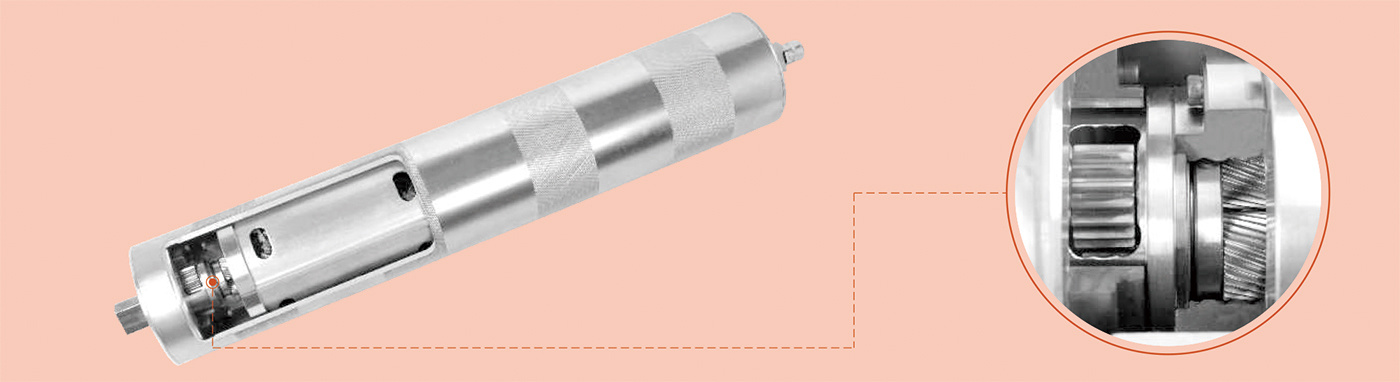

■ DM/DMX113 Characteristics Of Drum Motor

● Drum Sheel

• Material of standard drum shell is mild steel, zinc plated, with ECO mark • Food garde shell is 304 stainless steel • Standard cylinder surface processing with non slip rller

● Gear Drive

• High alloy steel grinding gear, to ensure the transmission of ultra low noise, aluminum gear box • Heavy load electric roller adopts planetary gear transmission, according to heavy load design, high torque transmission

● Motor

• When 50Hz or 60Hz is used, it can be applied to all kinds of universal voltage • Motor insulation class F • All motor additional overheat protector • Oil immersed motor cooling • Cable outlet type, cable length of 1.2M

● Seal Level

• Double seal design for shaft end • Drum motor sealing protection level is IP66/IP67

● Oiling

• Electric roller factory before has according to the standard oil • Every 5000 hours to run oil change time

● Other

• Horizontal insallation • Can be equipped with electromagnetic brake, but the shortest length of the cylinder will be extended accordingly • Belt speed and tube length can be produced according to customer requirements • According to customer requirements, can produce a variety of non - standard electric roller

■ DM113 Mechanical Parameters Of Three Phase Light Load Drum Motor

PN

kW

np

gs

i

V

m/min

nA

min-1

MA

Nm

FN

N

SL,min

mm

0.18

4

2

11.28

42.49

119.7

12.8

227

280

12.82

37.38

105.3

14.5

257

280

15.09

31.76

89.50

17.1

303

280

3

21.23

22.57

63.60

24.1

426

280

24.34

19.69

55.50

27.6

489

280

27.65

17.33

48.80

31.4

555

280

32.69

14.66

41.30

37.1

657

280

41.49

11.55

32.50

47.1

833

280

0.25

2

2

11.28

88.12

248.2

8.60

152

280

12.82

77.54

218.4

9.70

172

280

15.09

65.87

185.6

11.5

203

280

3

21.23

46.82

131.9

16.1

286

280

24.34

40.84

115.0

18.5

327

280

27.65

35.95

101.3

21.0

327

280

32.69

30.41

85.70

24.8

440

280

41.49

23.96

67.50

31.5

558

280

0.30

4

2

11.28

42.49

119.7

21.3

378

320

12.82

37.38

105.3

24.2

429

320

15.09

31.76

89.50

28.5

505

320

3

21.23

22.57

63.60

37.9

671

320

24.34

19.69

55.50

43.5

769

320

27.65

17.33

48.80

49.4

874

320

32.69

14.66

41.30

58.4

1033

320

41.49

11.55

32.50

74.1

1311

320

0.37

2

2

11.28

88.12

248.2

12.7

225

320

12.82

77.54

218.4

14.4

255

320

15.09

65.87

185.6

17.0

300

320

3

21.23

46.82

131.9

22.5

399

320

24.34

40.84

115.0

25.8

457

320

27.65

35.95

101.3

29.4

520

320

32.69

30.41

85.70

34.7

614

320

41.49

23.96

67.50

44.0

780

320

PN: Rated power

i: Reduction ratio of

MA: Electric drum rated torquenp: Series

v: 0utside the rated speed

FN: Traction forcegs: Gear series

nA: Outer tube rated speed

SLMin:The shortest outer tube length

■ DMX113 Mechanical Parameters Of Three Phase Heavy Load Drum Motor

PN

kW

np

gs

i

V

m/min

nA

min-1

MA

Nm

FN

N

SL min

mm

0.15

4

2

9.860

48.63

137.0

7.80

138

260

12.01

12.07

112.4

9.60

168

260

15.26

31.41

88.50

12.1

214

260

17.63

27.18

76.60

14.0

247

260

20.99

22.84

64.30

16.7

294

260

24.66

19.44

54.80

19.6

345

260

27.38

17.50

49.30

21.8

383

260

30.82

15.55

43.80

24.5

432

260

36.07

13.29

37.40

28.7

505

260

39.70

12.07

34.00

31.6

556

260

49.62

9.660

27.20

39.5

695

260

0.18

4

2

9.860

48.63

137.0

9.40

166

260

12.01

12.07

112.4

11.5

202

260

15.26

31.41

88.50

14.6

256

260

17.63

27.18

76.60

16.8

296

260

20.99

22.84

64.30

20.0

353

260

24.66

19.44

54.80

23.5

414

260

27.38

17.50

49.30

26.1

460

260

30.82

15.55

43.80

29.4

518

260

36.07

13.29

37.40

34.5

606

260

39.70

12.07

34.00

37.9

667

260

49.62

9.660

27.20

47.4

834

260

0.25

4

2

9.860

48.63

137.0

13.1

230

300

12.01

12.07

112.4

15.9

280

300

15.26

31.41

88.50

20.2

356

300

17.63

27.18

76.60

23.4

412

300

20.99

22.84

64.30

27.8

490

300

24.66

19.44

54.80

32.7

576

300

27.38

17.50

49.30

36.3

639

300

30.82

15.55

43.80

40.9

719

300

36.07

13.29

37.40

47.8

842

300

39.70

12.07

34.00

52.7

927

300

49.62

9.660

27.20

65.8

1158

300

0.37

4

2

9.860

48.63

137.0

19.3

340

300

12.01

12.07

112.4

23.6

415

300

15.26

31.41

88.50

30.0

527

300

17.63

27.18

76.60

34.6

609

300

20.99

22.84

64.30

41.2

725

300

24.66

19.44

54.80

48.4

852

300

27.38

17.50

49.30

53.7

946

300

30.82

15.55

43.80

60.5

1065

300

36.07

13.29

37.40

70.8

1246

300

39.70

12.07

34.00

77.9

1372

300

49.62

9.660

27.20

97.4

1714

300

0.55

2

2

9.860

100.86

284.1

3.9

244

300

12.01

82.77

233.2

16.9

297

300

15.26

65.15

183.5

21.5

378

300

17.63

56.37

158.8

24.8

437

300

20.99

47.36

133.4

29.5

520

300

24.66

40.31

113.6

34.7

611

300

27.38

36.31

102.3

38.5

678

300

30.82

32.25

90.90

43.4

763

300

36.07

27.55

77.60

50.8

893

300

39.70

25.04

70.50

55.9

983

300

49.62

20.03

56.40

69.8

1229

300

PN: Rated power

i: Reduction ratio of

MA: Electric drum rated torquenp: Series

v: 0utside the rated speed

FN: Traction forcegs: Gear series

nA: Outer tube rated speed

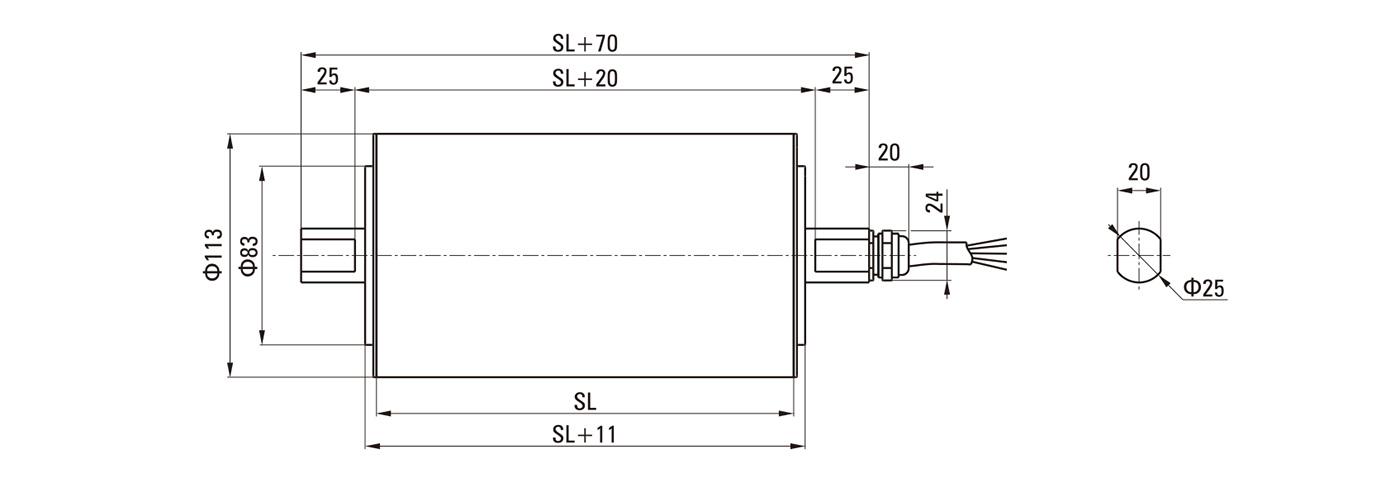

SLMin:The shortest outer tube length■ DM/DMX113 Outlining Dimensions

Standard Drum Length And Weight:

Outer Tube Length SL Unit:mm

250

300

350

400

450

500

550

600

650

700

750

800

850

Average Weight Unit: Kg

8.50

9.20

9.80

10.5

11.1

11.8

12.4

3.0

13.7

14.4

5.0

15.7

16.3

Maximum Power (kW)

4P

0.37

2P

0.55

Slowest Ratio

49.62

Minimum Speed Ratio

9.86

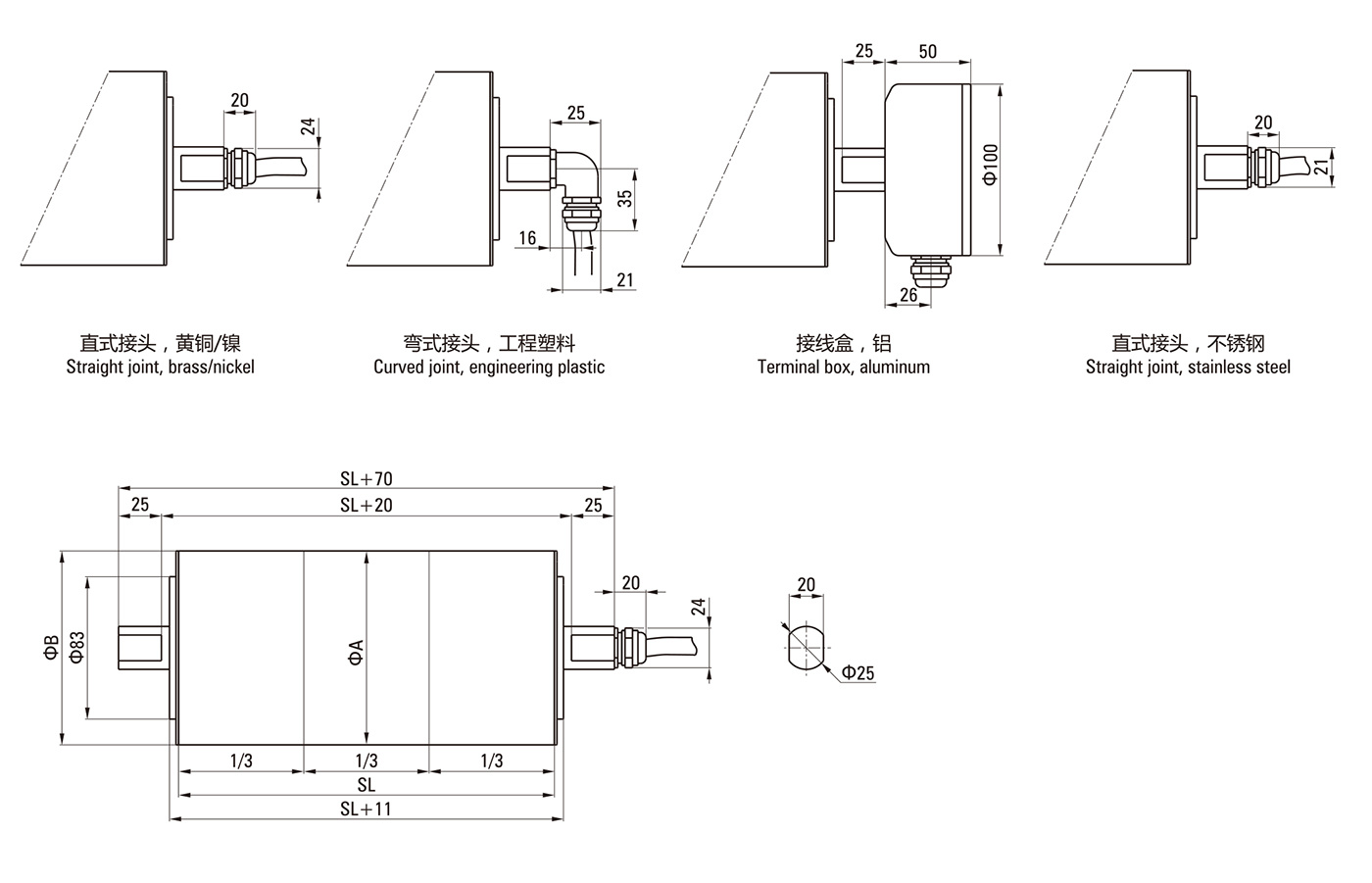

■ DM/DMX113 Installation Diagram

Type

ΦA

mm

ΦB

mm

113i tube

113.5

112.0

113i cylindrical tube

113.0

113.0

113i cylindrical tube + key

113.0

113.0

■ DM/DMX1 13 Option - Drum Motor

Component Description

Drum Motor

Drum shell

Carbon steel tube body

1

Carton steel straight drum

2

Stainless steel (standard 304) coronal tube body

2

Stainless steel (standard 304) straight drum

2

Special coronal and groove type

3

Front end cover

Cast aluminum cover

1

Nickel plated aluminum cover

2

Stainless steel (standard 304) end cover

2

Front and rare shaft

Carbon steel shaft

1

Stainless steel shaft

2

Motor

Single phase or three phase asynchronous motor

1

Voltage 1*220V/50Hz or 3*380V/50Hz

1

Global common voltage under 50Hz or 60Hz conditions

1

Thermal protector

1

Low temperature environment

2

Food grade oil&fat (FDA and USDA)

2

Eectrical connection

Stainless steel elbow

3

Straight curved line

1

PVC cable

1

Low smoke halogen free cable

2

Cast terminal box

1

Nickel plated aluminum terminal box

1

Stainless steel terminal box

2

Other options

Electromagnetic stop device

2

Vertical or inclined installation

3

Connected converter

2

Note:

1-Standard option 2-Non-standard option 3-Restrained option, contact manufacturer if needed

RELATED PRODUCTS

MESSAGES

If you have any questions, you can leave us a message. We have professionals to reply to you. Please fill in the correct contact information!

Contact

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd.

Add.: No. 185 Xinxing 1st Road, Cixi High-tech Industrial

Development Zone, Ningbo

Tel: +86-574-63537171

Fax: +86-574-63534879

WhatsApp: +86-19136773454

E-mail: trade20@zd-motor.comFollow us on social:

Copyright © Ningbo Zhongda Leader Intelligent Transmission Co., Ltd. All Right Reserved. Powered by www.300.cn SEO Business license

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

-