We look forward to providing you with professional services - Zhongda Leader

-

-

-

RV Cycloidal Pin Wheel Reducer

PRODUCTS

+Detail

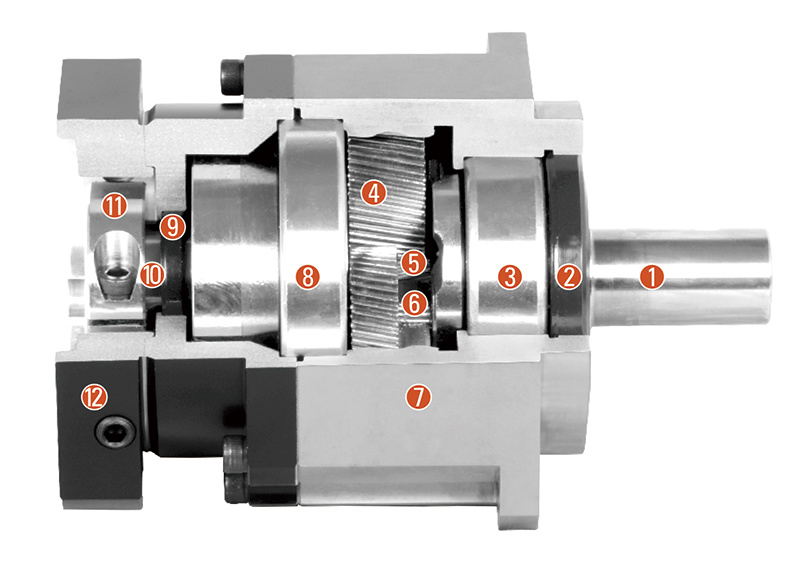

■ Sectional View

1. Output shaft

2. Oil seal

3. Output shaft front bearing

4. Planetary gear

5. Solar wheel

6. Full needle bearing

7. Front cover

8. Output shaft rear bearing

9. Oil seal

10. Coupling

11. Lock ring

12. Rear cover■ Type and Model Number Explanation

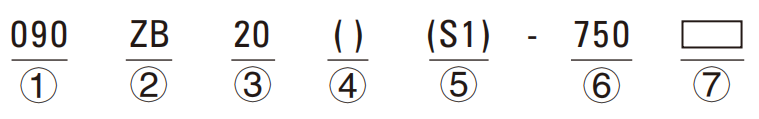

ZB Reducers Servo Motor

Gearbox frame size: 090 (See P04)

Gearbox series code: ZB

Gear ratio: 20, (See P04)

Precision (SeeP04)

Precision type P1,high pricision type P0

Output shaft load is ±5% of allowable output torque

Input shaft type

S1: Locking with locking ring (Omission)

(Can be used regardless whether the motor has a keyway, but “D” type is not applicable)

S2: Locking with keyway (Input shaft with key)

A: Other adapters (Please contact our company)

Applicable servo motor power (W)

Servo motor model

■ Reducer Performance Data

Specifications

Node Number

Reduction Ratio

042ZB

060ZB

060(A)ZB

090ZB

090(A)ZB

115ZB

142ZB

180ZB

220ZB

Rated Output Torque T2N

Nm

1

3

-

55

-

130

-

208

342

588

1140

4

19

50

-

140

-

290

542

1050

1700

5

22

60

-

160

-

330

650

1200

2000

6

20

55

-

150

-

310

600

1100

1900

7

19

50

-

140

-

300

550

1100

1800

8

17

45

-

120

-

260

500

1000

1600

9

14

40

-

100

-

230

450

900

1500

10

14

40

-

100

-

230

450

900

1500

2

15

-

55

55

130

130

208

342

588

1140

20

19

50

50

140

140

290

542

1050

1700

25

22

60

60

160

160

330

650

1200

2000

30

20

55

55

150

150

310

600

1100

1900

35

19

50

50

140

140

300

550

1100

1800

40

17

45

45

120

120

260

500

1000

1600

45

14

40

40

100

100

230

450

900

1500

50

22

60

60

160

160

330

650

1200

2000

60

20

55

55

150

150

310

600

1100

1900

70

19

50

50

140

140

300

550

1100

1800

80

17

45

45

120

120

260

500

1000

1600

90

14

40

40

100

100

230

450

900

1500

100

14

40

40

100

100

230

450

900

1500

Emergency Stop Torque T2NOT2

Nm

1,2

3~100

3 Times of Output Rated Torque

Rated Input Speed n1N

rpm

1,2

3~100

3000

3000

3000

3000

3000

3000

3000

3000

2000

Rated Input Speed n1B

rpm

1,2

3~100

6000

6000

6000

6000

6000

6000

6000

6000

4000

Super Precision Backlash PO

arcmin

1

3~10

-

-

-

-

-

≤1

≤1

≤1

≤1

2

15~100

-

-

-

-

-

≤3

≤3

≤3

≤3

Precision Backlash P1

arcmin

1

3~10

≤3

≤3

-

≤3

-

≤3

≤3

≤3

≤3

2

15~100

≤5

-

≤5

≤5

≤5

≤5

≤5

≤5

≤5

Standard Backlash P2

arcmin

1

3~10

≤5

≤5

-

≤5

-

≤5

≤5

≤5

≤5

2

15~100

≤7

-

≤7

≤7

≤7

≤7

≤7

≤7

≤7

Torsional Stiffness

Nm/arcmin

1,2

3~100

2

7

7

14

14

25

50

145

225

Allowable Radial Force F2rB3

N

1,2

3~100

780

1530

1530

3250

3250

6700

9400

14500

50000

Allowable Axial Force F2aB3

N

1,2

3~100

390

765

765

1625

1625

3350

4700

7250

25000

Service Life

hr

1,2

3~100

20000*

Efficiency η

%

1

3~10

≥97%

2

15~100

≥94%

Weight

Kg

1

3~10

0.6

1.3

-

3.7

-

7.8

14.5

29

48

2

15~100

0.8

1.5

1.9

4.1

5.3

9

17.5

33

60

Operating Temperature

℃

1,2

3~100

-10℃~+90℃

Lubrication

1,2

3~100

Synthetic Lubricating Grease

Protection Class

1,2

3~100

IP65

Mounting Position

1,2

3~100

Any Direction

Noise Level at 1m Distance (n1 =3000rpm, No Load)

dB(A)

1,2

3~100

≤56

≤58

≤60

≤60

≤63

≤63

≤65

≤67

≤70

■ Moment of Inertia of The Reducer

Specifications

Node Number

Reduction Ratio

042ZB

060ZB

060(A)ZB

090ZB

090(A)ZB

115ZB

142ZB

180ZB

220ZB

Moment Of Inertia J1

Kg·cm2

1

3

-

0.16

-

0.61

-

3.25

9.21

28.98

69.61

4

0.03

0.14

-

0.48

-

2.74

7.54

23.67

54.37

5

0.03

0.13

-

0.47

-

2.71

7.42

23.29

53.27

6

0.03

0.13

-

0.45

-

2.65

7.25

22.75

51.72

7

0.03

0.13

-

0.45

-

2.62

7.14

22.48

50.97

8

0.03

0.13

-

0.44

-

2.58

7.07

22.59

50.84

9

0.03

0.13

-

0.44

-

2.57

7.04

22.53

50.63

10

0.03

0.13

-

0.44

-

2.57

7.03

22.51

50.56

2

15

-

0.03

0.13

0.13

0.47

0.47

2.71

7.42

23.29

20

0.03

0.03

0.13

0.13

0.47

0.47

2.71

7.42

23.29

25

0.03

0.03

0.13

0.13

0.47

0.47

2.71

7.42

23.29

30

0.03

0.03

0.13

0.13

0.47

0.47

2.71

7.42

23.29

35

0.03

0.03

0.13

0.13

0.47

0.47

2.71

7.42

23.29

40

0.03

0.03

0.13

0.13

0.47

0.47

2.71

7.42

23.29

45

0.03

0.03

0.13

0.13

0.47

0.47

2.71

7.42

23.29

50

0.03

0.03

0.13

0.13

0.44

0.44

2.57

7.03

22.51

60

0.03

0.03

0.13

0.13

0.44

0.44

2.57

7.03

22.51

70

0.03

0.03

0.13

0.13

0.44

0.44

2.57

7.03

22.51

80

0.03

0.03

0.13

0.13

0.44

0.44

2.57

7.03

22.51

90

0.03

0.03

0.13

0.13

0.44

0.44

2.57

7.03

22.51

100

0.03

0.03

0.13

0.13

0.44

0.44

2.57

7.03

22.51

1.Gear ratio(i=Nin/Nout)

2.Maximum acceleration torque T2B=60% of T2NOT

3.When the output speed is 100rpm, it will act on the central position of the output shaft.

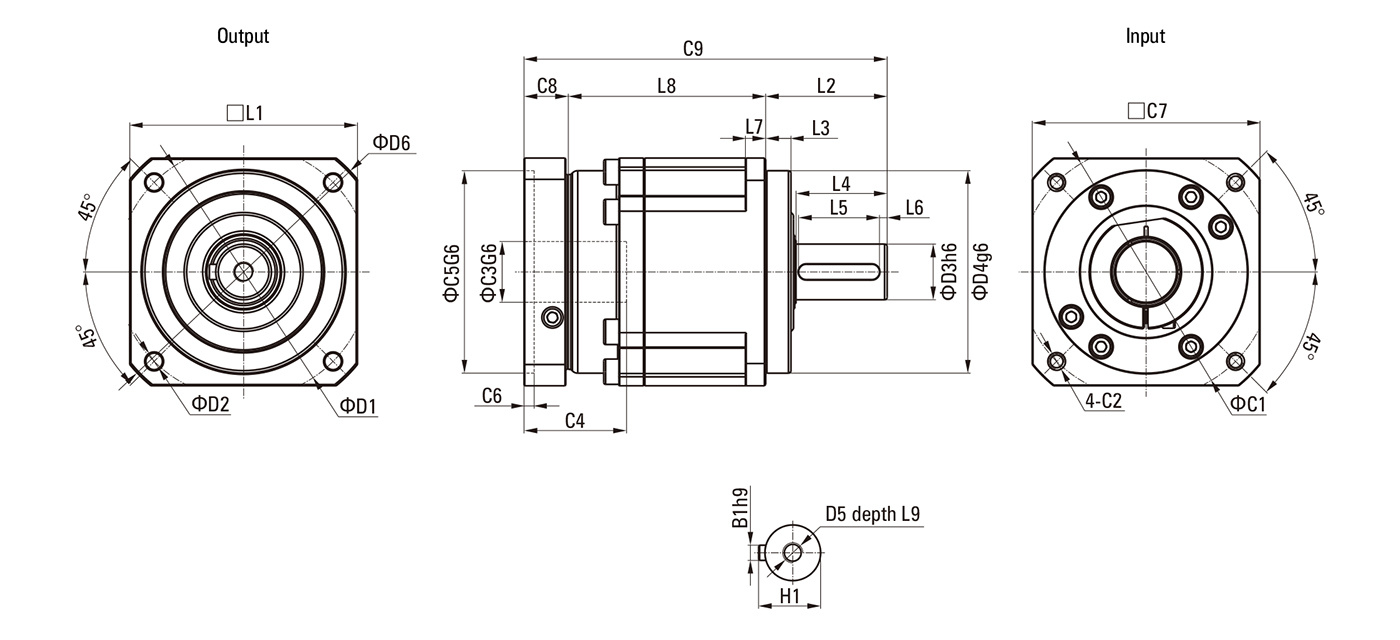

*Continuous operation, service life is 10000hrsDIMENSIONS (SINGLE STAGE, REDUCTION RATIO i=3~10)

■ Dimensional Drawing

■ Dimensional Table

Unit: mm

Size

042ZB

060ZB

090ZB

115ZB

142ZB

180ZB

220ZB

D1

50

70

100

130

165

215

250

D2

3.4

5.5

6.6

9

11

13

17

D3 h6

13

16

22

32

40

55

75

D4 g6

35

50

80

110

130

160

180

D5

M4×0.7P

M5×0.8P

M8×1.25P

M12×1.75P

M16×2P

M20×2.5P

M20×2.5P

D6

56

80

116

152

185

240

292

L1

42

60

90

115

142

180

220

L2

26

37

48

65

97

105

138

L3

5.5

7

10

12

15

20

30

L4

1

28

35.5

51

79

82

105

L5

16

25

32

40

70

70

90

L6

2

2

2

5

4

6

7

L7

4

6

8

10

15

20

25

L8

31

65.5

78

101.5

119.5

154

163.5

L9

4.8

12.5

19

28

36

42

42

C1

46

70

100

130

165

215

235

C2

M4×0.7P

M5×0.8P

M6×1P

M8×1.25P

M10×1.5P

M12×1.75P

M12×1.75P

C3

* ≤11/≤12

* ≤14/≤16

≤19/≤24

≤32

≤35/≤38

≤42/≤48

≤55

C4

25

35

40.5

51

60

85

116

C5 G6

30

50

80

110

130

180

200

C6

3.5

8

4

5

6

6

6

C7

42

60

90

115

142

190

220

C8

29.5

19.5

17.5

20

22.5

29

63

C9

114

122

143.5

186.5

239

288

364.5

B1 h9

5

5

6

10

12

16

20

H1

15

18

24.5

35

43

59

79.5

*060ZB 5,10 Reduction ratio provides C3≤16 to choose from.

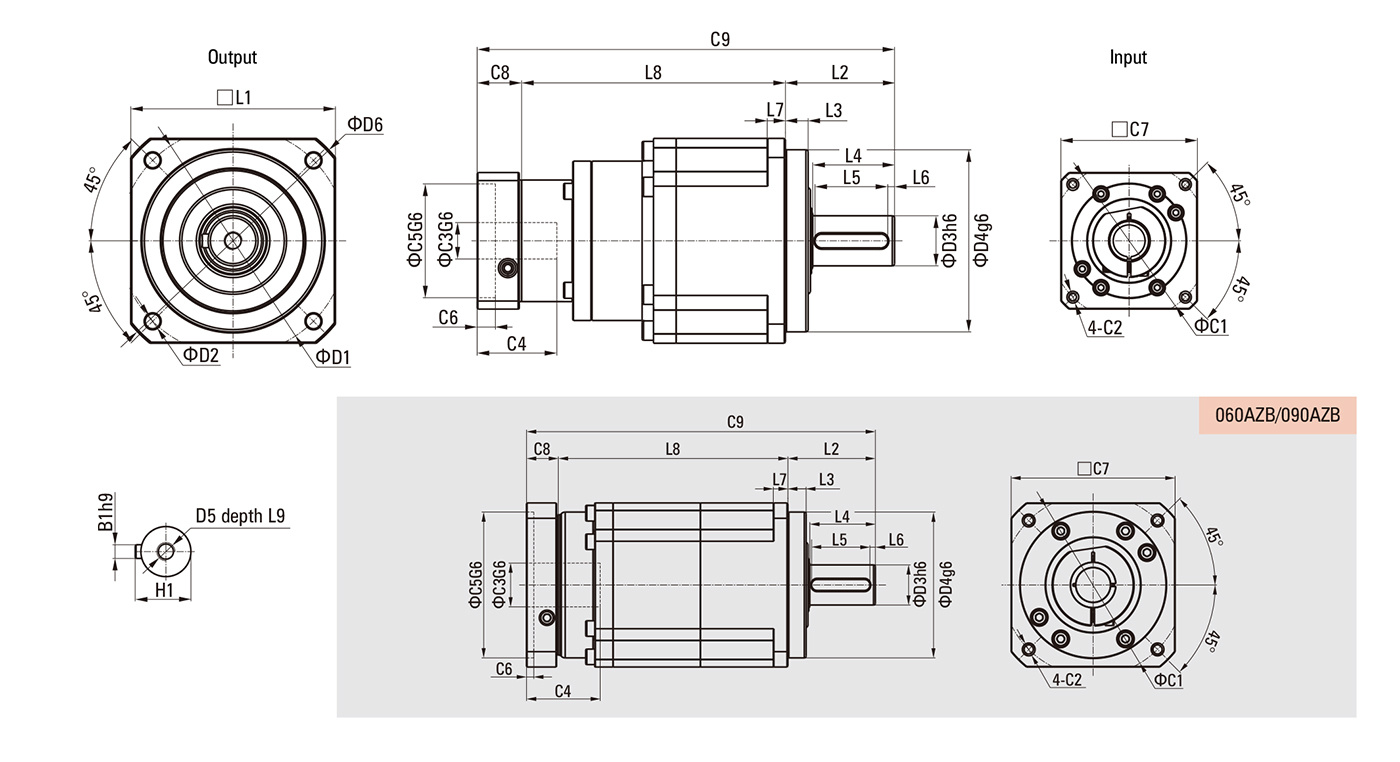

DIMENSIONS (TWO STAGE, REDUCTION RATIO i=15~100)

■ Dimensional Table

■ Dimensional Table

Unit: mm

Size

042ZB

060(A)ZB

090ZB

090(A)ZB

115ZB

142ZB

180ZB

220ZB

D1

50

70

100

130

165

215

250

D2

3.4

5.5

6.6

9

11

13

17

D3 h6

13

16

22

32

40

55

75

D4 g6

35

50

80

110

130

160

180

D5

M4×0.7P

M5×0.8P

M8×1.25P

M12×1.75P

M16×2P

M20×2.5P

M20×2.5P

D6

56

80

116

152

185

240

292

L1

42

60

90

115

142

180

220

L2

26

37

48

65

97

105

138

L3

5.5

7

10

12

15

20

30

L4

1

28

36

51

79

82

105

L5

16

25

32

40

70

70

90

L6

2

2

3

5

4

6

7

L7

4

6

8

10

15

20

25

L8

58.5

102.5

116

126

143

169.5

207.5

246

L9

10

12.5

19

28

36

42

42

C1

46

70

70

100

100

130

165

215

C2

M4×0.7P

M5×0.8P

M5×0.8P

M6×1P

M6×1P

M8×1.25P

M10×1.5P

M12×1.75P

C3

≤11/≤12

≤14/≤16

≤14/≤15.875/≤16

≤19/≤24

≤19/≤24

≤32

≤35/≤38

≤42/≤48

C4

25

35

35

40.5

40

50

60

85

C5 G6

30

50

50

80

80

110

130

180

C6

3.5

8

8

4

4

5

6

6

C7

42

60

60

90

90

115

142

190

C8

29.5

19.5

19.5

17.5

17.5

12.5

22.5

29

C9

114

159

183.5

191.5

225.5

283.5

335

409

B1 h9

5

5

6

10

12

16

20

H1

15

18

24.5

35

43

59

79.5

RELATED PRODUCTS

MESSAGES

If you have any questions, you can leave us a message. We have professionals to reply to you. Please fill in the correct contact information!

Contact

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd.

Add.: No. 185 Xinxing 1st Road, Cixi High-tech Industrial

Development Zone, Ningbo

Tel: +86-574-63537171

Fax: +86-574-63534879

WhatsApp: +86-19136773454

E-mail: trade20@zd-motor.comFollow us on social:

Copyright © Ningbo Zhongda Leader Intelligent Transmission Co., Ltd. All Right Reserved. Powered by www.300.cn SEO Business license

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

-