We look forward to providing you with professional services - Zhongda Leader

-

-

-

RV Cycloidal Pin Wheel Reducer

PRODUCTS

+servo motor driver In the world of mechanical and electrical systems, the integration of servo motor, driver, and planetary gearbox is a remarkable combination that brings forth numerous benefits and capabilities.

Detail

In the world of mechanical and electrical systems, the integration of servo motor, driver, and planetary gearbox is a remarkable combination that brings forth numerous benefits and capabilities.The servo motor provides the essential force and motion control, allowing for precise and rapid adjustments. Its ability to accurately position and move is crucial in various applications, from industrial machinery to robotics.

The driver acts as the brain of the system, regulating the power and signals to the servo motor. It ensures smooth and efficient operation, optimizing the performance of the motor and enabling fine-tuning for specific tasks.

When combined with the planetary gearbox, a whole new level of functionality emerges. The planetary gearbox offers torque multiplication, enabling the system to handle heavier loads and provide more power. It also helps in achieving different speed ratios, giving flexibility in adapting to different operating requirements.

This integrated setup offers several advantages. Firstly, it simplifies the overall system design, reducing the complexity and number of components. This leads to more compact and streamlined installations.

Secondly, it enhances the reliability and durability of the system. With fewer components, there are fewer potential points of failure, and the well-matched combination of the servo motor, driver, and gearbox ensures consistent performance over time.

Moreover, this integration allows for better control and synchronization. The coordinated operation of these elements leads to more accurate and efficient movements, which is essential in applications where precision is key.

In conclusion, the integration of servo motor, driver, and planetary gearbox is a powerful combination that unlocks a world of possibilities in various industries. It provides a seamless and efficient solution for achieving precise motion control, torque, and performance. As technology continues to advance, we can expect this integrated approach to play an even more significant role in driving innovation and excellence in mechanical and electrical systems.

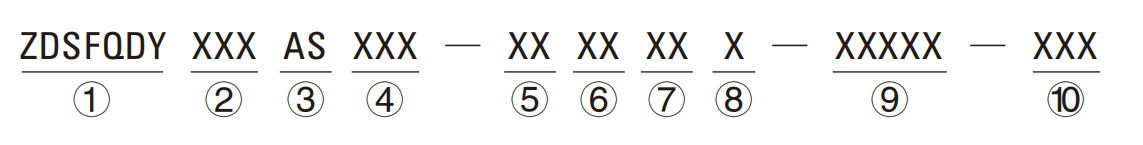

①

ZDSFQDY

Zhongda servo drive all-in-one machine

②

电机机座号 Motor size

06: 60mm, 08: 80mm, 13: 130mm, 18: 180mm...

③

AS系列 Series

AS: 小惯量

AM: 中惯量

AL: 大惯量

AS: Small inertia

AM: Medium inertia

AL: large inertia

④

Power level

040: 400W, 075: 750W, 085: 850W...

⑤

Speed (*100r/min)

30: 3000r/min, 20: 2000r/min ...

⑥

Encoder

A1: 17 bit single coil absolute value optical

11: 1000 line incremental optical

M1: 1024 line incremental magnetic

R1: A pair of polar rotation

⑦

Brakes

None: Omitted, M: With brake (24VDC)

⑧

Driver voltage

C: Single-phase 220V Single-phase 220V

S: Three-phase 220V Three-phase 220V

S3: Three-phase 380V Three-phase 380V

24: 24VDC

48: 48VDC

⑨

Reducer acceleration ratio

Planetary ZA speed ratio of 9... (This item does not indicate that there is no speed reducer)

⑩

The feature code of the driver

B: With brake resistance

C: CAN communication function

R: 485 communication function

S: STO function

● ⑥ pou

Encoder

A1

17-digit single circumference absolute photoelectric encoder

I2

A 2,500-line incremental photoelectric encoder

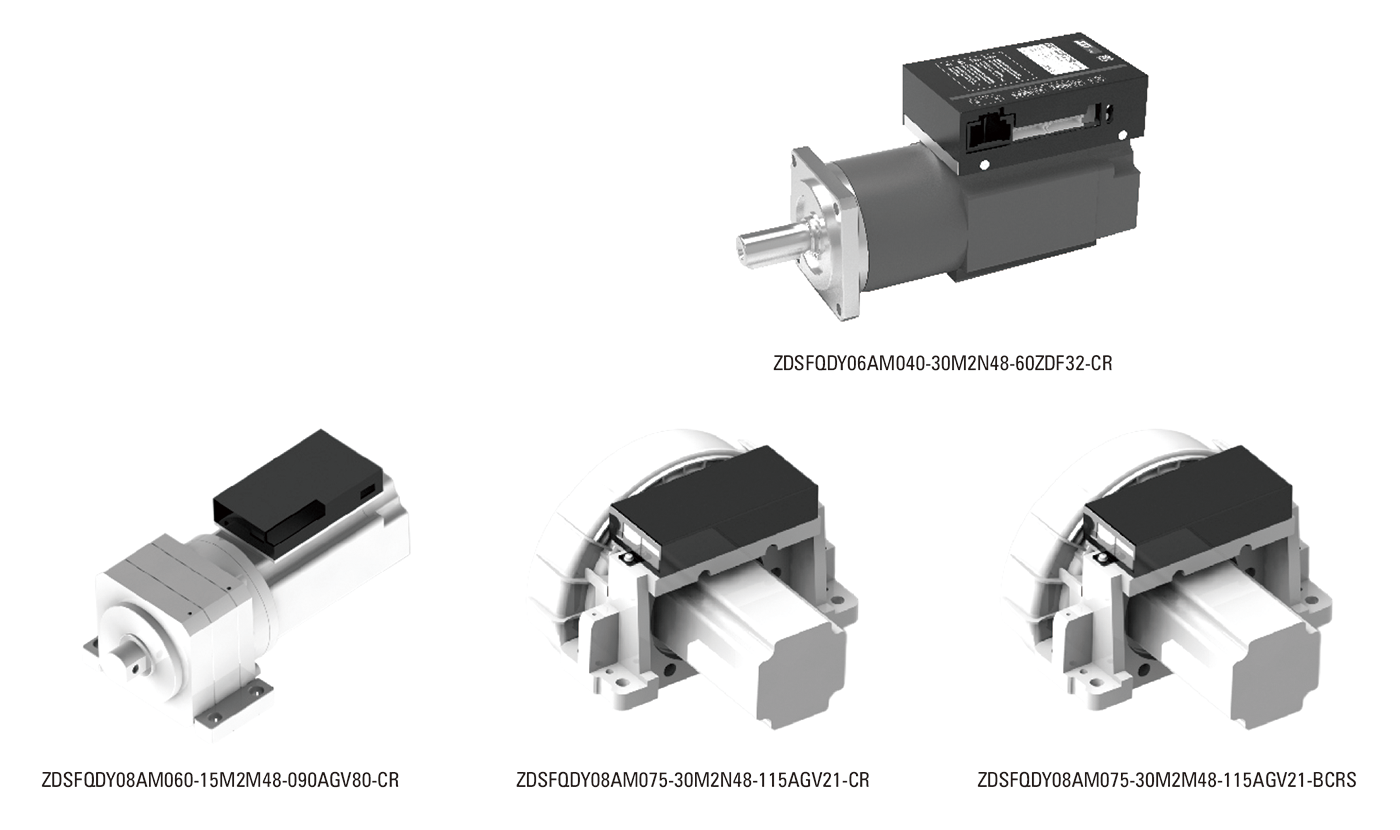

■ Features of servo motor & driver&planetary gearbox integrated

· Small volume.

· High transmission efficiency.

· Simple connection.

· Convenient application

■ Specifications

Model parameters

Servo motor & driver&planetary gearbox integrated

ZDSFQDY06AM040-30M2N48

-60ZDF32-CR

DSFQDY08AM060

-15M2M48- 090AGV80-CR

ZDSFQDY08AM075-30M2N48

-115AGV21-CR

ZDSFQDY08AM075-30M2M48

-115AGV21-BCRS

Rated control electrical input voltage

48VDC

Rated power electrical input voltage

48VDC

Output current

Rated current (rms)

12Arms

18Arms

22Arms

Peak current (peak)

50.4Ap

75.6Ap

92.4Ap

ncoder

Incremental (Differential, 2500 line)

Energy-consumption brake resistance

No

No

5Ω, 60W

leak resistance

No

No

1Ω, 50W

Energy-consumption brake voltage

DC60V±1V

Overvoltage alarm voltage

DC65V±1V

Under voltage alarm voltage

DC40V±1V

Overload time

2.5~3 times overload, maximum duration of 3 seconds

Cooling method

Free cooling

General

functions

Digital input

2 way, support PNP and NPN connection, total COM1 terminal, High level 12V~24VDC

Digital output

1-way, OC gate output, maximum working voltage 30VDC, maximum current 150mA

Protection function

Undervoltage protection, overvoltage protection, overload protection, software overcurrent protection,

over temperature protection, hardware overcurrent protection, stall protection, blocking protection,

excessive position deviation, encoder disconnection protection, etc

Upper computer

Can use 485 communication to connect to computer upper computer software,

set parameters, capture waveforms, and upgrade programs

CANopen

Maximum support of 1M wave rate

Usage

environment

Working temperature

-25~40℃ ; Derating usage above 40 degrees Celsius

Storage temperature

-10℃~70℃

Humidity

Below 90% RH, without condensation

Protection class

IP20

Height

When the working altitude is above 1000 meters and below 1000 meters, a derating of 1.5% is required for every

100 meters increase. The maximum working altitude is 4000 meters

Pressure

86kpa~106kpa

■ Specifications

Model parameters

Servo motor & driver & planetary gearbox integrated

ZDSFQDY06AM040-30M2N48 -60ZDF32-CR

ZDSFQDY08AM060-15M2M48 -090AGV80-CR

ZDSFQDY08AM075-30M2N48

-115AGV21-CR

ZDSFQDY08AM075-30M2M48

-115AGV21-BCRS

Output power

400W

600W

750W

Number of poles

10

8

8

Rated voltage

48VDC

48VDC

48VDC

Rated speed

3000RPM

1500RPM

3000RPM

Maximum speed

4000RPM

2000RPM

4500RPM

Rated torque

1.27N.m

3.82N.m

2.38N.m

Torque coefficient

/

0.21N.m/Arms

0.125N.m/Arms

Rotor inertia

/

0.19*10-3kgm2

0.18*10-3kgm2

Line resistance

0.056Ω

0.34Ω

0.084Ω

Linear inductance

0.14mH

0.99mH

0.31mH

Back electromotive force coefficient

11V/Krpm

14.5V/KRPM

7.3V/KRPM

Rated current

12A

18A

22A

Working duty

1min

S2 (5min)

S2 (60min)

Insulation class

F Level

F Level

F Level

Protection class

IP20

IP20

IP20

Ambient temperature

0-+40℃

0-+40℃

0-+40℃

Encoder

2500

Linear magnetic braiding

2500

Linear magnetic braiding

2500

Linear magnetic braiding

Reduction ratio

32:1

80:1

21:1

Gearbox stage

/

2

2

Rated output torque

/

180N.m

45N.m

Permissible radial load

/

10249N

8000N

Allowable axial load

/

3300N

2000N

Backlash (arcmin)

≤10

≤25

≤25

Rated torque of reducer

38N.m

38N.m

/

Instantly withstand maximum torque

Twice the rated torque

/

/

Transmission efficiency

94%

/

/

Noise

≤65dB(A) 100cm

≤65dB(A) 100cm

≤65dB(A) 100cm

<tr style="background-color:#e4e4e4;"> <td colspan="2" rowspan="2"> <p>Model parameters</p> </td> <td colspan="3"> <p>Servo motor & driver&planetary gearbox integrated</p> </td> </tr>

RELATED PRODUCTS

MESSAGES

If you have any questions, you can leave us a message. We have professionals to reply to you. Please fill in the correct contact information!

Contact

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd.

Add.: No. 185 Xinxing 1st Road, Cixi High-tech Industrial

Development Zone, Ningbo

Tel: +86-574-63537171

Fax: +86-574-63534879

WhatsApp: +86-19136773454

E-mail: trade20@zd-motor.comFollow us on social:

Copyright © Ningbo Zhongda Leader Intelligent Transmission Co., Ltd. All Right Reserved. Powered by www.300.cn SEO Business license

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

-