We look forward to providing you with professional services - Zhongda Leader

-

-

-

RV Cycloidal Pin Wheel Reducer

PRODUCTS

+Brushless Driver The C41 Series Non-Inductive Driver is at the forefront of industrial motion control, delivering unparalleled precision and efficiency. This advanced driver leverages cutting-edge non-inductive technology to ensure smooth and reliable operation across a wide range of applications. With its state-of-the-art design, it offers enhanced performance and longevity, making it ideal for industries that demand rigorous standards.

Detail

The C41 Series Non-Inductive Driver is at the forefront of industrial motion control, delivering unparalleled precision and efficiency. This advanced driver leverages cutting-edge non-inductive technology to ensure smooth and reliable operation across a wide range of applications. With its state-of-the-art design, it offers enhanced performance and longevity, making it ideal for industries that demand rigorous standards.

In the manufacturing sector, the C41 Series excels in tasks requiring high-speed and high-precision movements. Its superior control algorithms enable seamless integration with various automation systems, ensuring accurate positioning and speed regulation. This level of precision is crucial for processes such as assembly lines, packaging machinery, and material handling systems, where even minor deviations can lead to quality issues or downtime.

Energy efficiency is a key differentiator of the C41 Series. By minimizing energy losses, these drivers contribute to reduced operational costs and lower environmental impact. Their efficient power management not only extends the lifespan of connected motors but also reduces heat generation, enhancing overall system reliability. This makes them particularly valuable in industries focused on sustainability and cost-effectiveness.

Versatility is another hallmark of the C41 Series. Designed to support multiple communication protocols, they effortlessly integrate into diverse industrial networks. Whether it's classic fieldbuses or modern industrial Ethernet standards, these drivers ensure seamless communication and easy setup. This adaptability allows users to upgrade their systems without significant modifications, providing a future-proof solution.

Safety features are integral to the C41 Series, incorporating overcurrent protection, thermal management, and fault diagnostics. These safety mechanisms safeguard both the driver and the connected equipment, preventing damage and ensuring continuous operation under adverse conditions. This robust safety framework provides peace of mind to operators and enhances the overall reliability of industrial processes.

User-friendly interfaces are a priority in the C41 Series. Intuitive controls and clear displays simplify configuration, monitoring, and troubleshooting. This ease of use minimizes training requirements and maximizes productivity, allowing operators to focus on critical tasks rather than navigating complex settings. The straightforward interface ensures that even novice users can operate the drive with confidence.

In summary, the C41 Series Non-Inductive Driver stands out in the realm of industrial motion control due to its precision, efficiency, versatility, and user-centric design. It caters to the evolving needs of modern industries, offering a reliable and sustainable solution that enhances operational excellence. As industries continue to embrace innovation, the C41 Series remains a cornerstone of progress, driving forward the future of automation.

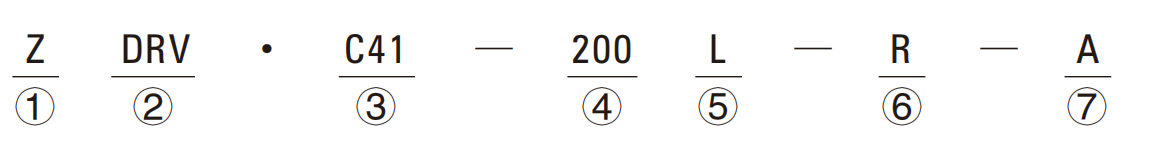

①

Company name abbreviation

Z: ZHONGDA LEADER

②

Product type

DRV: Drivers and related products

③

Product series

C41: Non-inductive driver series

④

Power level

Low pressure: 120:120W 200:200W 400:400W

High pressure: 120:120W 200:200W 400:400W

⑤

Power supply type

S2: Single-phase AC220V/50Hz~60Hz

L: DC24V~DC48V

⑥

Function code

D: With digital display

B: With braking function

R: With 485 communication function

⑦

Appearance structure

A: Panel type

B: Built-in type

■ Features of C41 series non-inductive drivers

· Only three motor power lines are needed: Fundamentally avoiding problems such as unreliable connection of motor encoder lines or Hall signal lines and signal interference, which can effectively improve the reliability of the system.

· No need for motor encoder or Hall sensor: Adopting a high-performance position sensorless solution, achieving sine wave FOC vector control of the motor, saving the wiring harness and terminals of the encoder or Hall, effectively reducing the overall cost of the system.

· Good low-speed performance: Excellent speed closed-loop control performance, with a minimum speed of up to 50rpm, and a speed ratio comparable to motor drives with encoders.

· Support heavy load on-load starting: Maximum allowable on-load starting at 150% of the rated load torque of the motor; If you need to start with load under higher load torque conditions, you can communicate with our company about product customization matters.

· Support for ultra long distance motor control: The maximum allowable distance for the three-phase power line between this product and the motor is 20 meters. If you need to support a longer distance, you can communicate with our company about product customization matters.

· Low speed fluctuation: Under rated speed conditions, the speed fluctuation is about 1%, and the excellent speed stability performance can be comparable to motors with encoders, meeting the needs of the vast majority of applications.

· Can support ultra high speed motors: Supports a maximum motor speed of up to 30000 rpm. If you need to support higher motor speeds, you can communicate with our company for customization.

· Strong applicability: With powerful automatic recognition function for motor parameters, this product can be compatible with various manufacturers of Hall free DC brushless motors and encoder free permanent magnet synchronous motors.

· High cost-effectiveness.■ Panel type

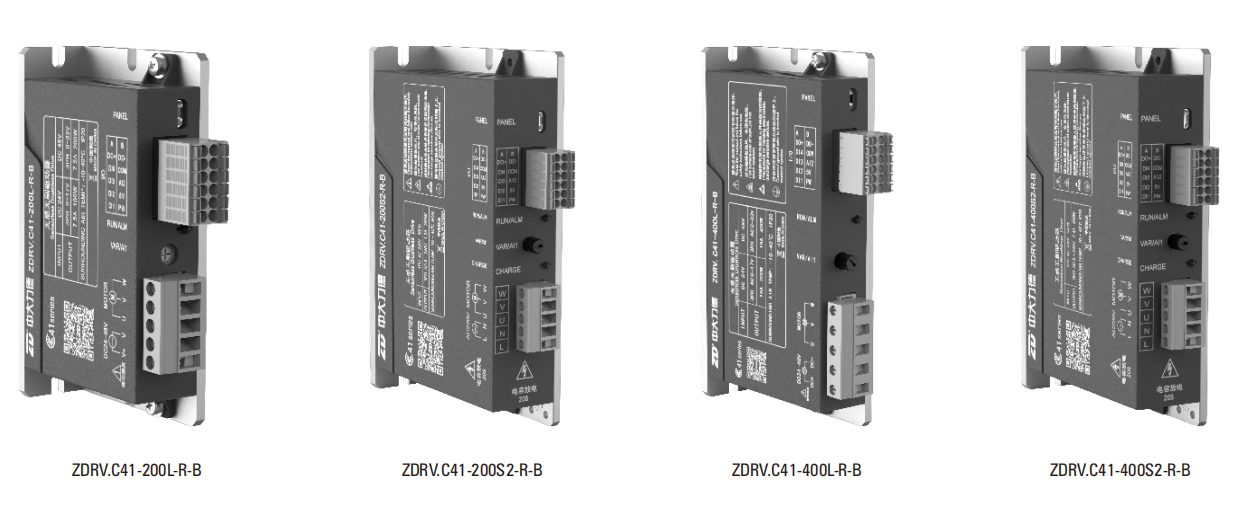

■ Internal type

■ Specifications

Model parameters

C41 Series non-inductive driver

C41-200L-R-A

C41-200S2-R-A

C41-400L-R-A

C41-400S2-R-A

C41-200L-R-B

C41-200S2-R-B

C41-400L-R-B

C41-400L-R-B

Rated input voltage

DC24V-DC48V

AC220V/50HZ

DC24V-DC48V

AC220V/50HZ

DC24V-DC48V

AC220V/50HZ

DC24V-DC48V

AC220V/50HZ

Output current

Rated current (rms)

7.5Arms

1.2Arms

15.0Arms

2.5Arms

7.5Arms

1.2Arms

15.0Arms

2.5Arms

Peak current (peak)

22.5Ap

4.0Ap

45.0Ap

8.0Ap

22.5Ap

4.0Ap

45.0Ap

8.0Ap

Energy consumption braking

No

Overvoltage alarm voltage

125% Rated voltage overvoltage

Under voltage alarm voltage

70% Rated voltage overvoltage

Overload time

150% rated current for 1 minute, 180% rated current for 10 seconds, and 200% rated current for 1 second

Cooling method

Free cooling, contact cooling

Digital input

3-way

(Supporting

NPN/PNP)

4-way

(Supporting

NPN/PNP)

4-way, supporting NPN/PNP, optocoupler input, high-level DC12V~DC30V, low-level DC0V~DC5V, input impedance 3K Ω

Digital input function

Forward running, reverse running, three-wire control, forward jogging, reverse jogging, free parking, fault reset, electronic braking, external fault input, forward limit, reverse limit, multi terminal speed selection, etc

Analog input

1路, DC0V~DC5V/10V, PWM (3KHZ~10KHZ)

Analog input function

Speed regulation, torque regulation

General

functions

Digital output

1 channel, optocoupler output, compatible with NPN/PNP support, maximum working voltage 60VDC,

maximum output current 100mA

Pulse control

No

Protection function

Undervoltage protection, overvoltage protection, overload protection, hardware overcurrent protection, software overcurrent protection, current limiting protection, over temperature protection, phase loss protection, locked rotor protection, etc

Upper computer

Not support

Support

Operation panel

Configurable Zhongda handheld operation panel, setting parameters and reading data

Bus control

Modbus/RS485

No

Supports a maximum baud rate of 115.2K and can communicate

with the controller using the Modbus RTU protocol

CANopen

No

Usage

environment

Working temperature

-20~40℃, derated for use above 40℃ . For every 1℃ increase, the rated current needs to be reduced by 2.5%.

The maximum operating temperature can reach 50℃

Storage temperature

-30 ℃~+60 ℃, with an air temperature change of less than 1℃/minute

Humidity

Below 90% RH, without condensation

Protection level

IP20

Installation method

Panel mounted

Built-in installation

Height

Used below 1000 meters; For use with a derating of over 1000 meters,

a derating of 1.5% is required for each 100 meter increase; Please test and confirm if the altitude is above 2000 meters

Pressure

86kpa~106kpa

RELATED PRODUCTS

MESSAGES

If you have any questions, you can leave us a message. We have professionals to reply to you. Please fill in the correct contact information!

Contact

Ningbo Zhongda Leader Intelligent Transmission Co., Ltd.

Add.: No. 185 Xinxing 1st Road, Cixi High-tech Industrial

Development Zone, Ningbo

Tel: +86-574-63537171

Fax: +86-574-63534879

WhatsApp: +86-19136773454

E-mail: trade20@zd-motor.comFollow us on social:

Copyright © Ningbo Zhongda Leader Intelligent Transmission Co., Ltd. All Right Reserved. Powered by www.300.cn SEO Business license

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

-